Call Us :

407/2A2 UVS NAGAR, MATHAMPALAYAM - 641 019, COIMBATORE, TAMILNADU, INDIA

Tube Inspections Services have been carried out by IRIS NDT Technologies personnel for the Petrochemical and Power Generation. We specialize in Eddy Current and Ultrasonic techniques for both ferrous and non-ferrous tubing. Our line of techniques includes:

3D MFL Tank Floor Scanning: IRIS NDT Technologies continues to invest in the latest Technology with the addition of the Silverwing Computerized Magnetic Flux Leakage (MFL)Floor map 3D scanner with STARS technology to provide discrimination between top and bottom surface defects.

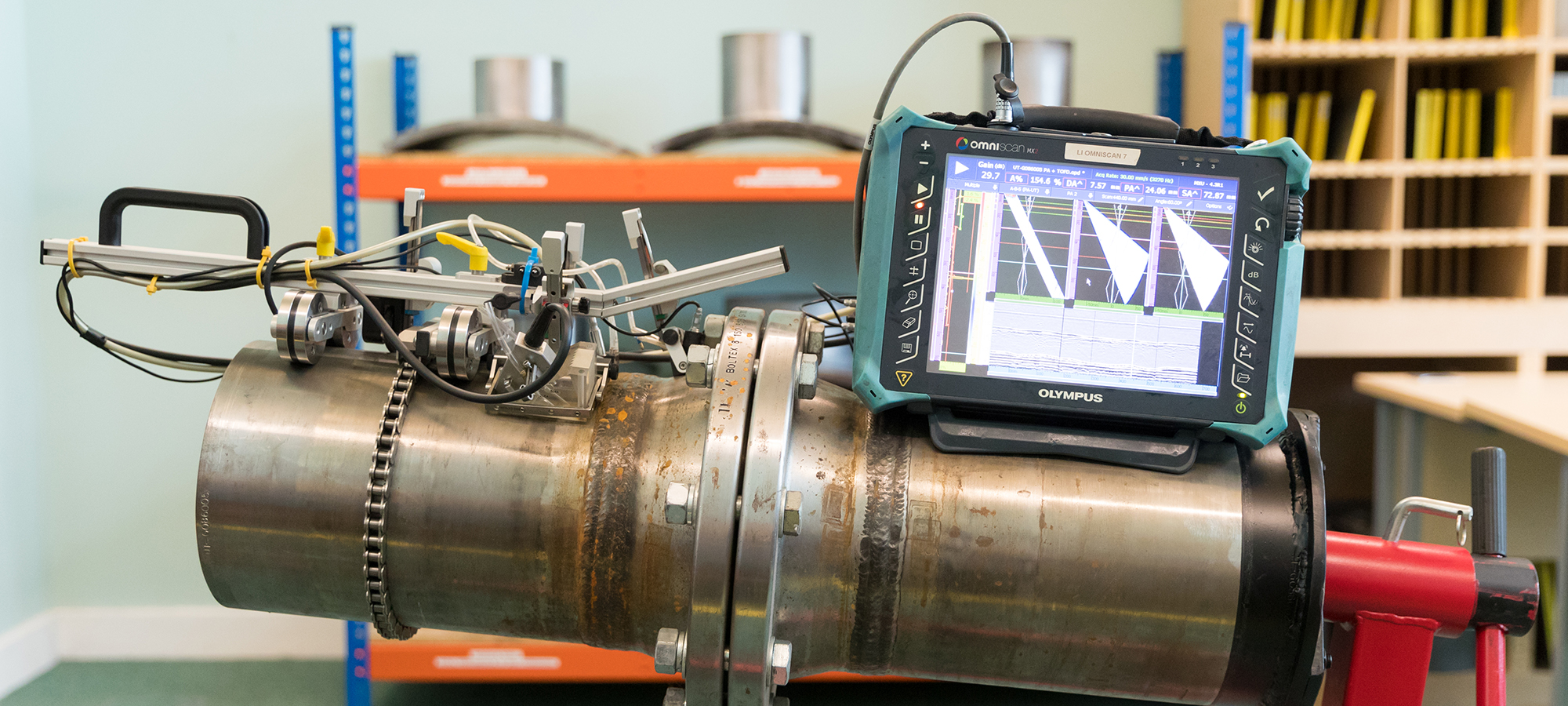

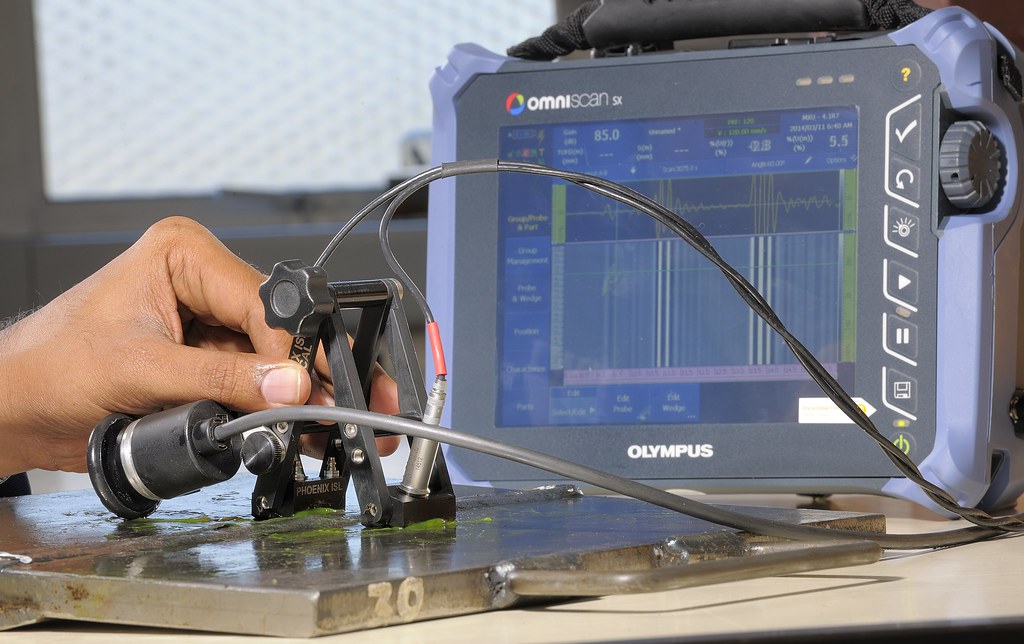

Welds and weld overlays, piping, pressure vessels, clad material, storage tanks and structural steel. Raised face flanges for damage on the ID bore and sealing face without having to disassemble them. This technique can be used during shutdowns, or on operating flanges. Complex geometries with a single probe

This ultrasonic inspection is commonly performed on welds and weld overlays, piping, pressure vessels, clad material, storage tanks and structural steel. As fabricated heavy wall vessels and piping can be thoroughly assessed for fabrication flaws with TOFD.

IRIS NDT Technologies provide a comprehensive Borescope Inspection Service. Borescope inspections are widely used in the Power Generation and Pharmaceutical Industry to visually inspect items of plant and machinery. In Pharmaceutical industry ASME BPE requires up to 100% borescope inspection of pipe work during construction. The Inspection Engineers at Advanced NDT Technologies have extensive experience carrying out borescope inspection for a number of leading mechanical engineering and pharmaceutical companies.