Call Us :

407/2A2 UVS NAGAR, MATHAMPALAYAM - 641 019, COIMBATORE, TAMILNADU, INDIA

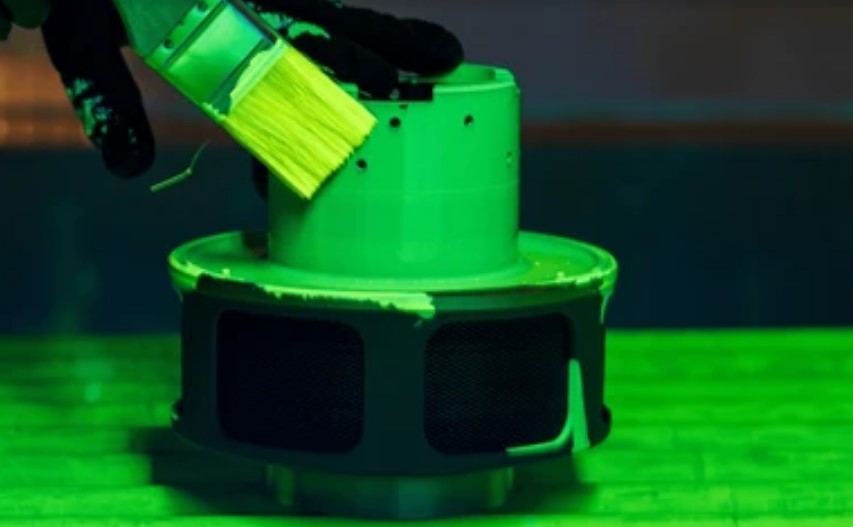

The non-destructive testing technology Magnetic Particle Inspection or MT as it is generally referred to be a simple crack detection tool for ferrous materials. MPI is used mainly for detecting surface breaking flaws. Some techniques will detect large sub-surface flaws. There are a number of levels of sensitivity and means of inducing magnetic fields in materials. The technique is determined by specific application and configuration of part to be inspected. In order to perform this inspection technique, it is a requirement to remove all coatings and have surface clean of dirt, scale and grease.

IRIS NDT Technologies personnel have extensive experience in DPI – Dye Penetrant Inspection – and LPI – Liquid Penetrant Inspection. IRIS’s experienced non destructive testing inspection engineers are certified to ASME and EN codes.

IRIS NDT Technologies certified Non Destructive Testing Inspection Engineers provide an extensive industrial radiography service. Radiography is a versatile NDT inspection technique providing a permanent record of findings.

IRIS NDT Technologies inspection engineers, provide ultrasonic inspection of welds and material our global clients. Our team has vast experienced and carries out inspections to all international standards. This is done using the most up to date equipment and techniques.